PLASTIC INJECTION

MOLDING

TOOLS FOR PLASTIC COMPONENTS MOLDING

JUNYI Plastic & Hardware Co., Ltd is a high-tech manufacturer of precision plastic molds that provide one-stop service for precision plastic mold design, manufacturing, injection molding, painting, silk screen printing and assembly. We are specializing in the development and manufacturing plastic products in consumer electronics, smart home, office equipment, automotive electronics, medical equipment and other industries, with 11 years of production experience, our company have formed high-volume industrial chain of mold design, manufacturing, injection molding, painting,silk screening, assembly etc. the monthly mold production capacity is up to 35 sets and the monthly production capacity is up to 1 million pieces, and the annual output value is as high as 20 million RMB.

Since its establishment in 2005, our factory covered an area of 3,000 square meters and more than 100 employees. For 11 years, we have been focusing on the R&D, manufacturing and large-scale production of precision plastic mold industry. With high quality molds and excellent service, JUNYI won The trust of all customers, and become a supplier of molds and plastic parts for Fortune 500 companies such as Lenovo, Panosonic, Belkin, Mophie and INCIPIO etc.

We adhere to the corporate vision of “To create a first-class mold enterprise with the goal of surpassing customer expectations”, to set up a factory in Quality, to cooperate with sincerity, and to provide professional and high-quality services to new and old customers, hold on together and create brilliant!

Our Tool Processing Equipment

-

Taiwan CNC machines

Stroking 500*1050mm -

Taiwan Innovation Symbiotic

Milling Machine -

Japanese Injection Molding Machines

-

Chinese Haitian Molding Machines

-

Second Floor Assembly Line

-

Coordinate Measuring Instrument

Stroking 500*800mm -

Two Dimensional Measuring Instrument

Stroking 210*320mm -

Japan Sodick Slow Wire Burn Device

Stroking 350*500mm -

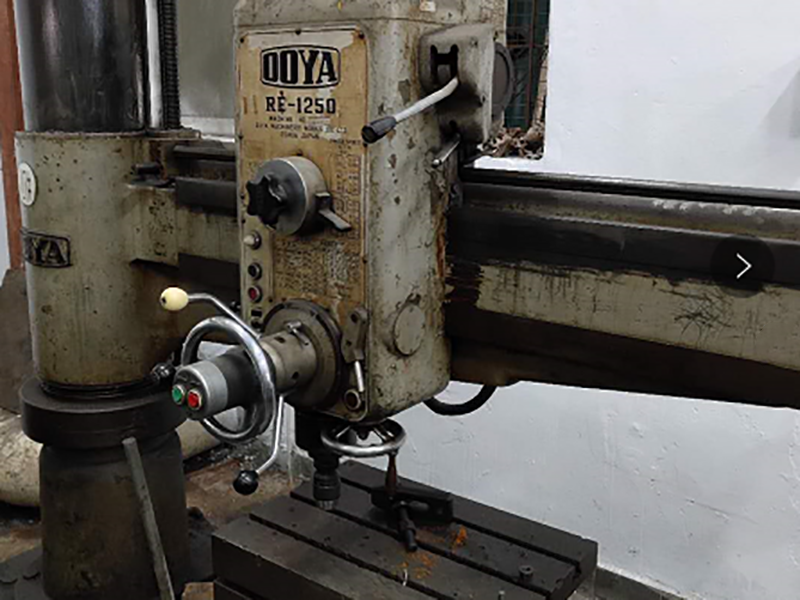

Japanese Drilling Machine

Stroking 1200*800mm -

Japanese Dimon shaddick EDM device

Stroking 220*450mm -

Taiwan EDM device

Stroking 450*750mm -

Taiwan Precise Small Grinding Machine

Stroking210*450mm

Production Cases

-

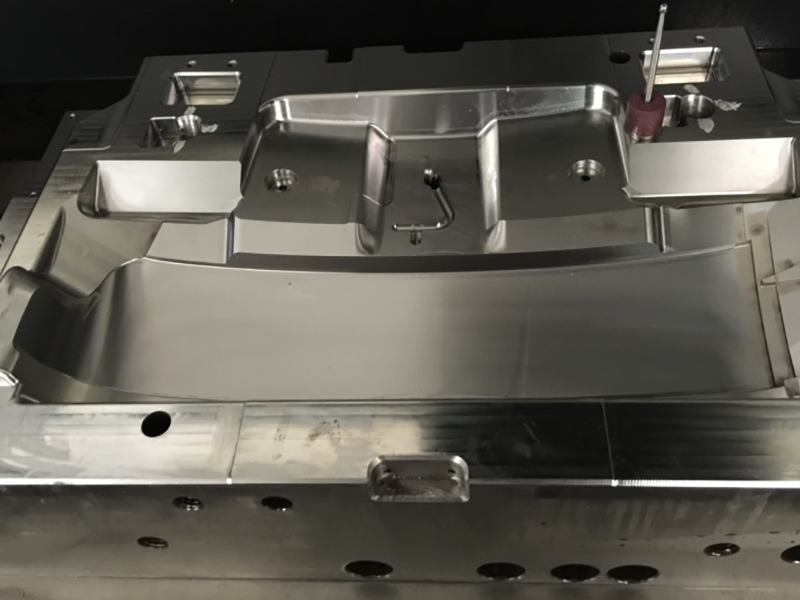

0.01mm tolerance mold

-

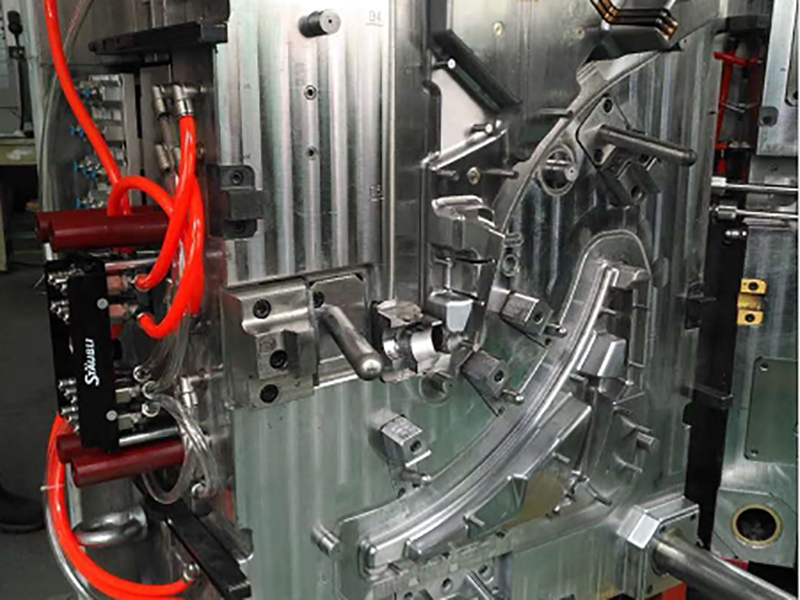

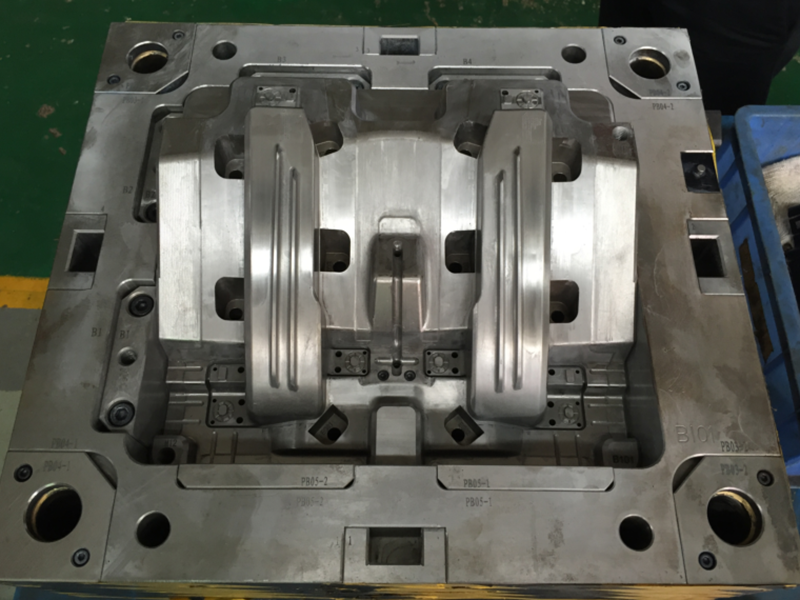

Audi Q5L water tank tool

-

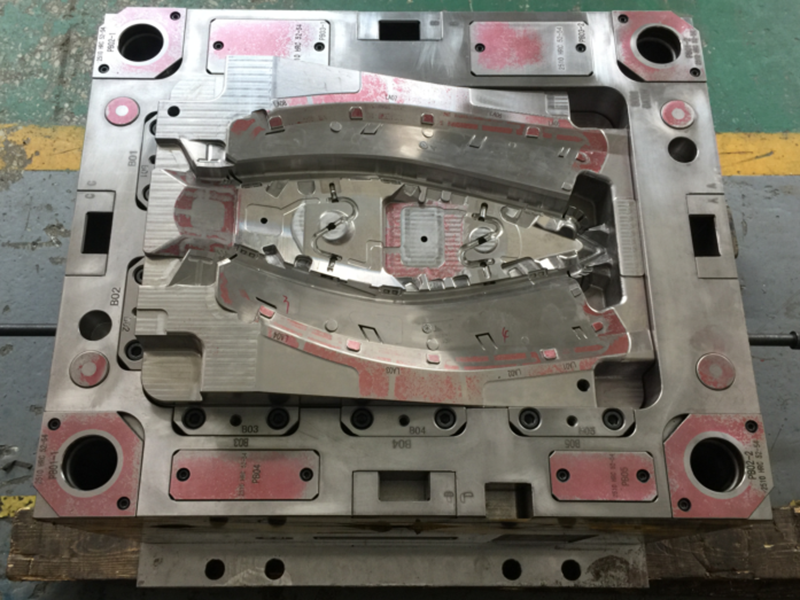

BMW light tool

-

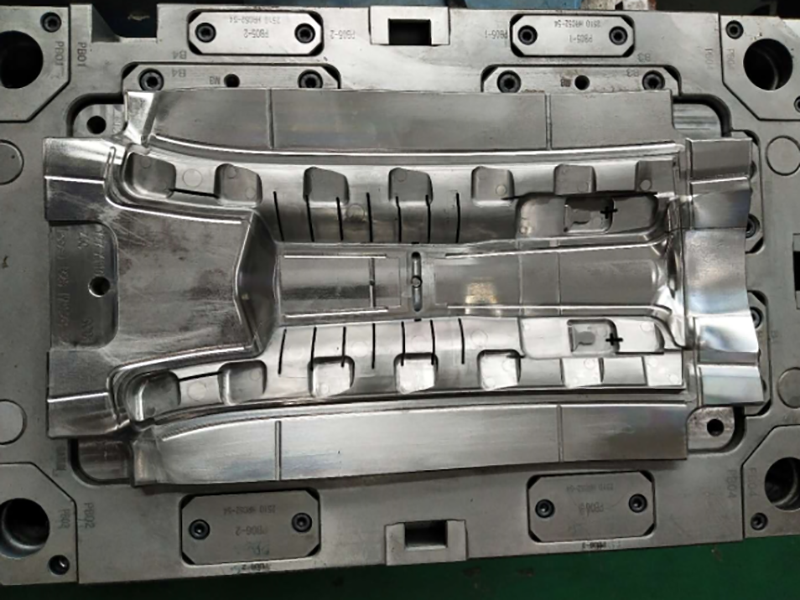

car light tool core

-

EDM processing cavity details

-

Mercedes-Benz light tool

-

Mold Assembly Checking

-

mold base processing details

-

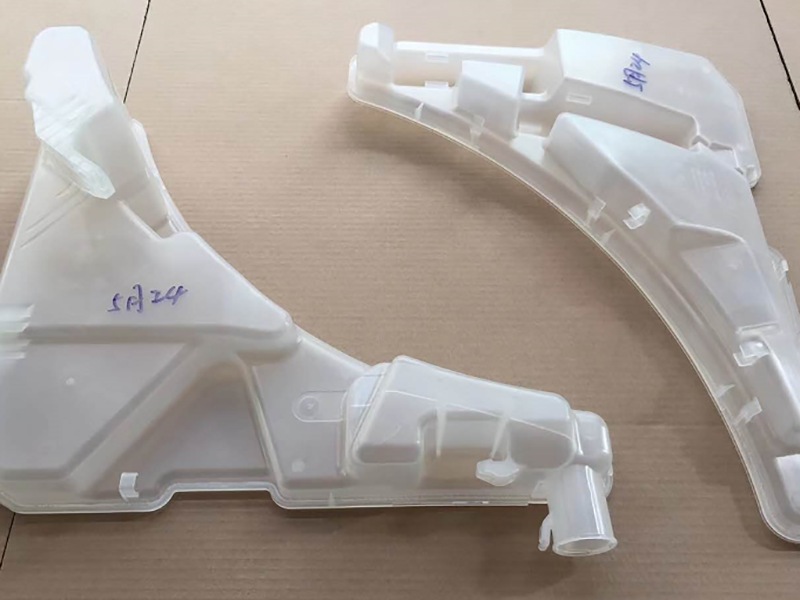

Molding Audi Q5L water tank

-

Molding BMW Part

-

Panosonic Molding Part

-

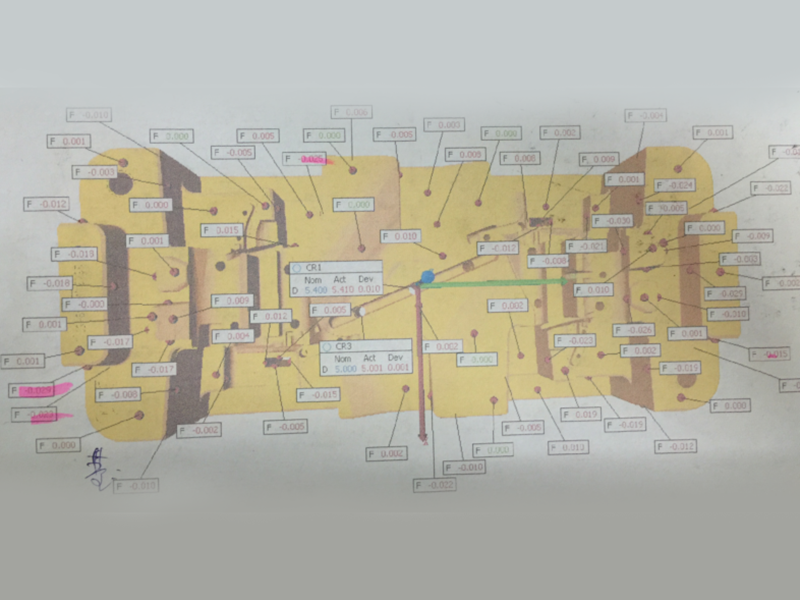

Tool Dimension Checking

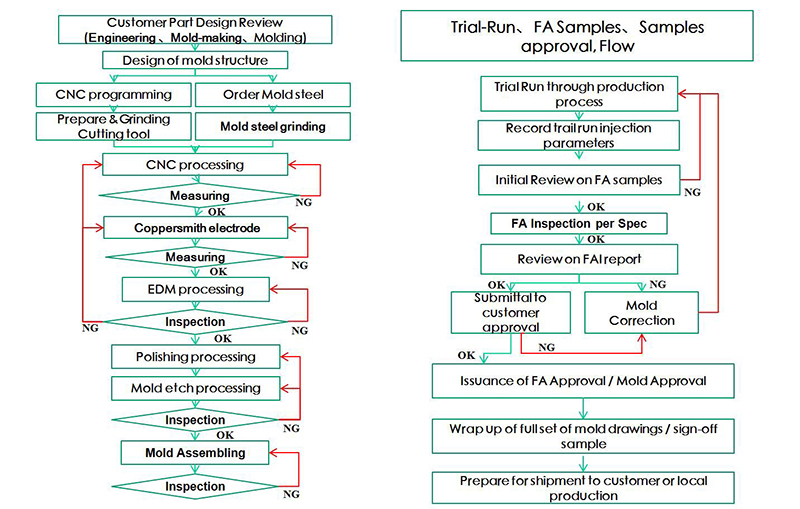

Our Working Flowing

- 1, 3D design/Samples for Quotation According to 3D drawing or sample to make

- 2, Negotiations Quotation and material, injection gates, surface finish, color, tolerance

- 3, Purchasing Order After customer confirming the mould design and receiving the deposit

- 4, Making Mold(Moulds/Tools) Confirm the final drawing, tool drawing

- 5, Production Schedule We will make a processing progress to customers once a week

- 6, Sample Shoot We provide moulds testing samples for confirmation (10-20 pcs free sample)

- 7, Package Wooden Case for moulds, Cartons for plastic parts, or pack as your requirements

- 8, Deliver Deliver by air or by sea, we will provide shipment comparison to you for choice

No matter small quantity or large quantity, we can meet your demands with the lowest cost; our engineer can evaluate your projects and choose the easy tools for your products, reducing the cost for your company.