CNC

MACHINING

SERVICES

PRECISION AND QUALITY

"Good Service & High Quality come from Profession", from establishment in 2005, JUNYI Plastic & Hardware Co.,Limited regards it as our company culture. All the employees are experienced in their own position, working together to make perfect products for our customers and gain a good reputation for our company at the same time. Among 200 employees, some of them are famous in our industry, JUNYI provides opportunities for stuffs to attend the industry technique communication meeting each month, employees from JUNYI company get the approval of the same trade and our clients. What’s more, the new workers must accept at least two weeks training before on duty. Quality is sure to be guaranteed.

A Comprehensive Resource in product development including engineering and rapid prototyping and manufacturing services in a variety of materials including both plastics and metals,which has three production departments Prototype Dept, Plastics Injection Dept and Metal Dept with more than ten years of experience.

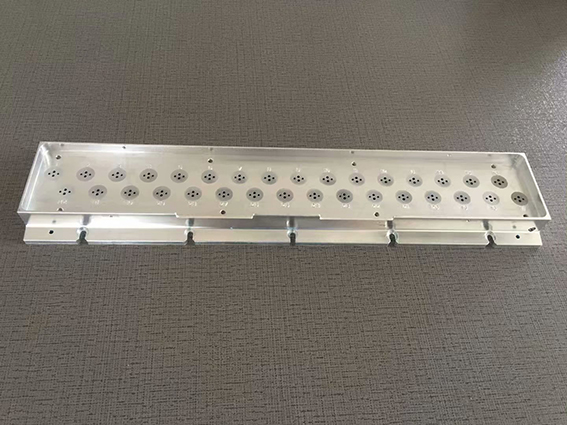

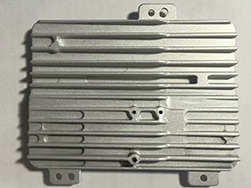

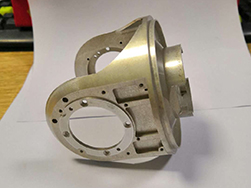

The CNC process is used over a span of industries with applications for:

- Mechanical parts

- Home appliances

- Decorative items

- Custom pieces, components, and more!

See what JUNYI can do for you. Contact us today and let’s talk about your upcoming CNC machining project!

WHAT IS CNC MACHINING?

CNC is the acronym for Computer Numeric Control. A computer numerically controlled machine tool is an automated machine tool with a program control system. The control system can logically process and decode the program with control code or other symbolic instructions to cause the machine to operate and machine the part.

CNC lathes are mainly used for large-scale machining of parts, including the outer circle, the boring, the plane and so on. Programs can be written for mass production and the automation of the production process is high. Since the development of the world's first CNC machine tool by the Massachusetts Institute of Technology in 1952, CNC machine tools have been widely used in the manufacturing industry, especially in the automotive, aerospace, and military industries. CNC technology has rapidly develop both in hardware and software.

CNC MILLING AND CNC TURNING

Depending on your needs, a CNC turning or CNC milling machine may be used in the production of your design.

CNC MILLING

CNC milling is the machining process used to machine prismatic parts. Milling cutters with a rotating cylindrical cutter head and multiple flutes are often referred to as end mills that can be moved along different axes for machining narrow spaces, grooves, outer contours, and the like. The milling machine is a versatile machine tool that can machine planes (horizontal, vertical), grooves (keyways, T-slots, dovetails, etc.), splitting parts (gears, spline shafts, sprockets) on the milling machine. Spiral surfaces (threads, spiral grooves) and various curved surfaces. In addition, it can also be used to process and cut the surface of the rotor and the inner hole.

CNC TURNING

CNC turning is the simplest CNC process, involving the use of a lathe to turn a plastic or metal part for precise cutting and boring. For exact external grooves and accurate holes, CNC Turning is your solution.

Depending on your project, CNC machining services may be the manufacturing solution you require. If you’re curious to know more, or would like to discuss a prototype or manufacturing project, give us a call. We are ready to assist you anytime. CNC projects are fast, accurate, and work with many different materials.

Various of materials used in CNC maching

Such as:

- Copper

- Aluminum

- Stainless steel

- Magnesium

- Titanium

- Nylon

- polycarbonate

We can produce CNC milled and turned parts in dozens of additional materials. If you’re curious to know which material is right for you, send us a line. Our designers and engineers will put their experience to work for you, helping determine the best possible materials and manufacturing solution for your prototype or manufacturing run. Your design, required tolerances, and budget will all help determine which materials are necessary and appropriate for your project.