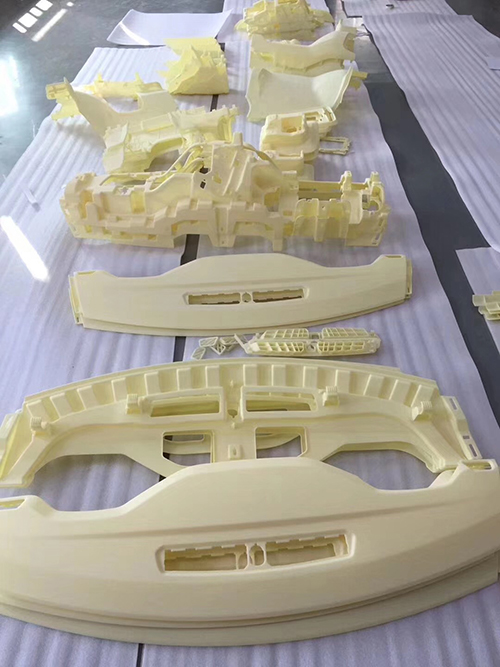

3D PRINTING SERVICES

SLA AND SLS

RAPID PROTOTYPING SERVICES

3D printing is a kind of rapid prototyping technology. It is a technique for constructing objects by layer-by-layer printing based on digital model files and using adhesive materials such as powdered metal or plastic.It is usually done using a digital technology material printer. It is often used in the manufacture of molds in the fields of mold manufacturing, industrial design, etc., and is gradually used for the direct manufacture of some products. There are already parts printed using this technology.

The technology is used in:

jewelry, footwear, industrial design, construction, engineering and construction (AEC), automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering, firearms and other fields.

SLA

SLA is an abbreviation for "Stereo lithography Appearance", which is a stereo photocuring method. Focusing on the surface of the photocurable material with a laser of a specific wavelength and intensity, from point to line, from line to surface solidification, complete a level of drawing operation, then move the lifting table vertically in the height of a layer, and then solidify Another level. This layer stacking constitutes a three-dimensional entity.

- Advantages of SLA technology:

- 1. High maturity, after the test of time.

- 2. The processing speed is fast and the production cycle is short.

- 3. It can process prototypes and molds with complex structural shapes or difficult to form using traditional methods.

- 4. Visualize the CAD digital model and reduce the cost of error repair.

- 5. Provide samples for the experiment, and verify the results of the computer simulation calculation.

- 6. It can be operated online and can be controlled remotely, which is conducive to the automation of production.

SLS

The SLS process uses a laser to selectively sinter solid powder layer by layer and layer to obtain the required parts. Compared to SLA technology, the SLS process uses an infrared laser beam (such as a CO2 laser) that changes from a liquid photosensitive resin to a powder of plastic, wax, ceramic, metal, and composites.

- The advantages of the SLS process are obvious:

- 1) Molding materials are very extensive.

- 2) Any complex structure can be printed, including hollow structures.

- 3) The material utilization rate is high, the unsintered powder can be reused, and the material waste is small;

- 4) No support structure is required.

- 5) SLS process can process standard plastics with good mechanical properties;